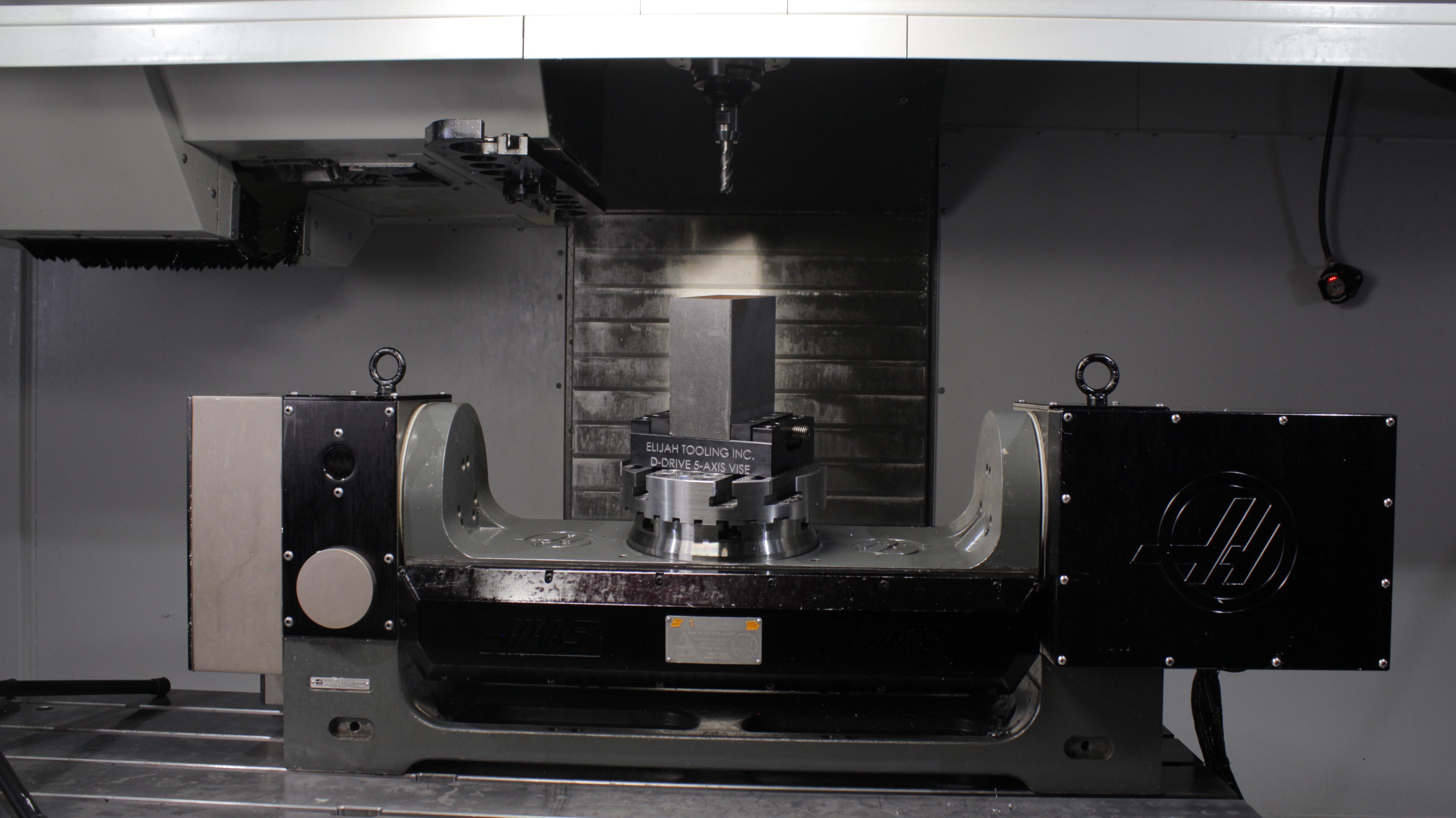

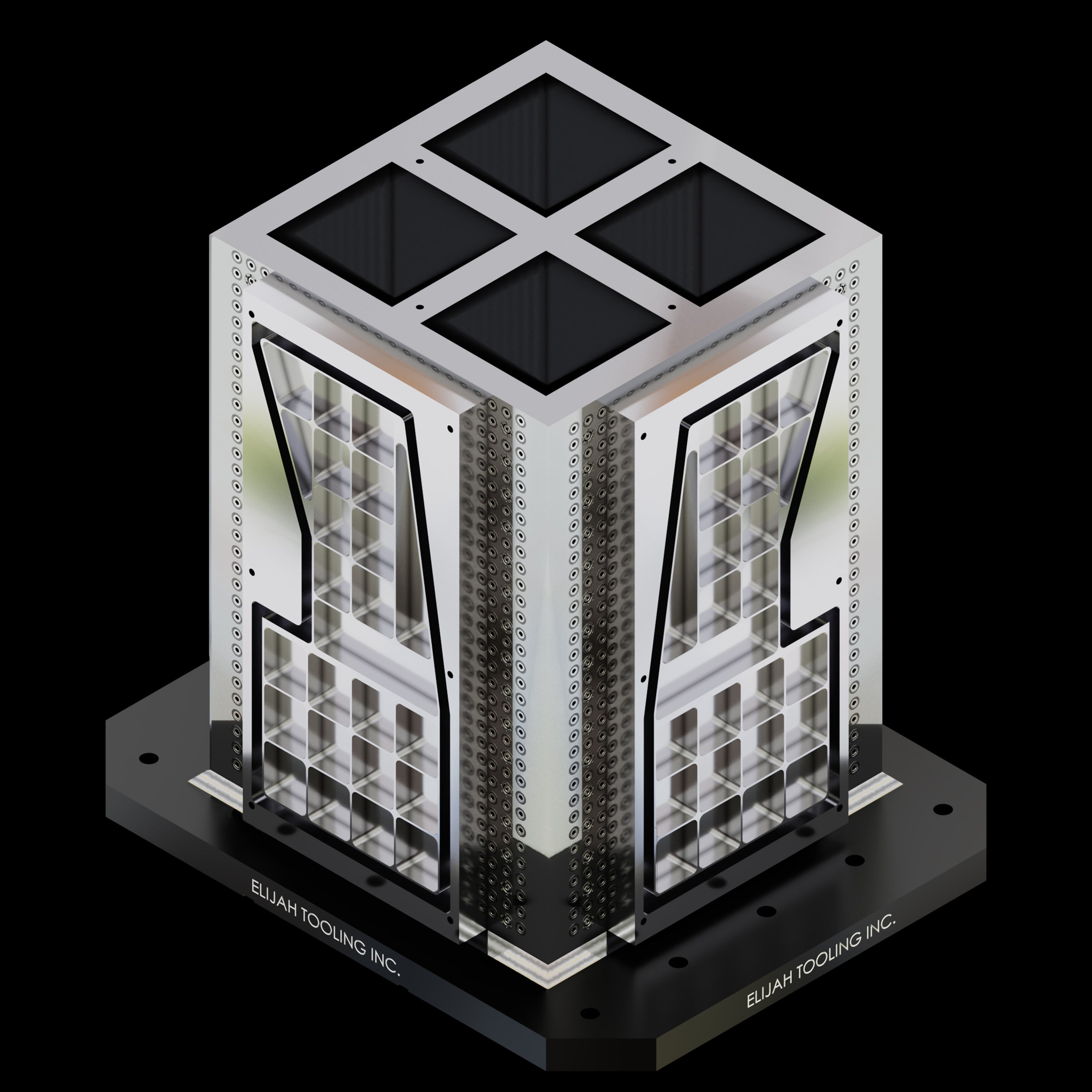

Workholding Tools

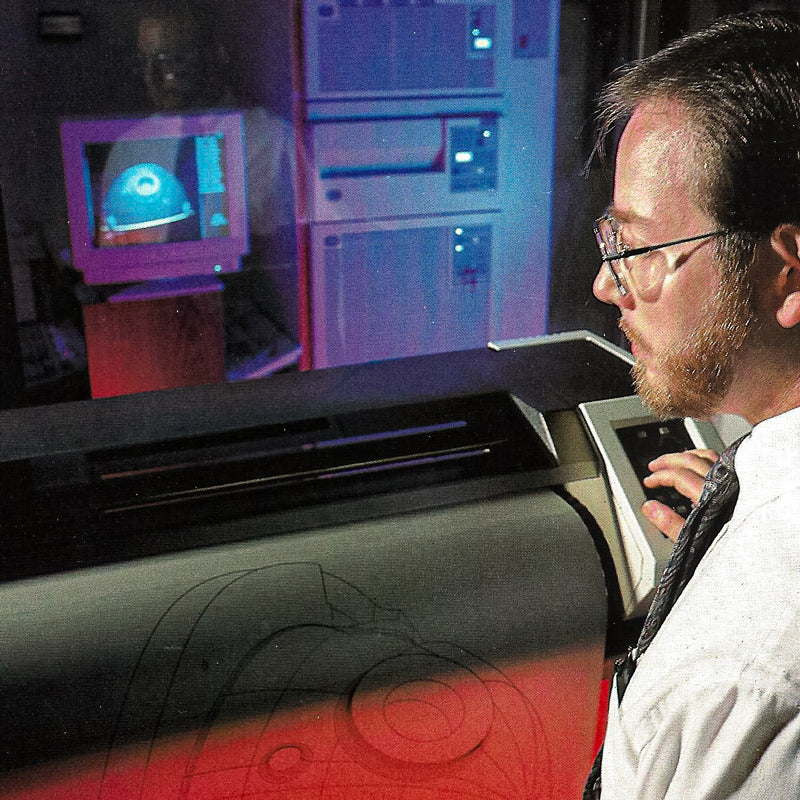

Behind the Scenes

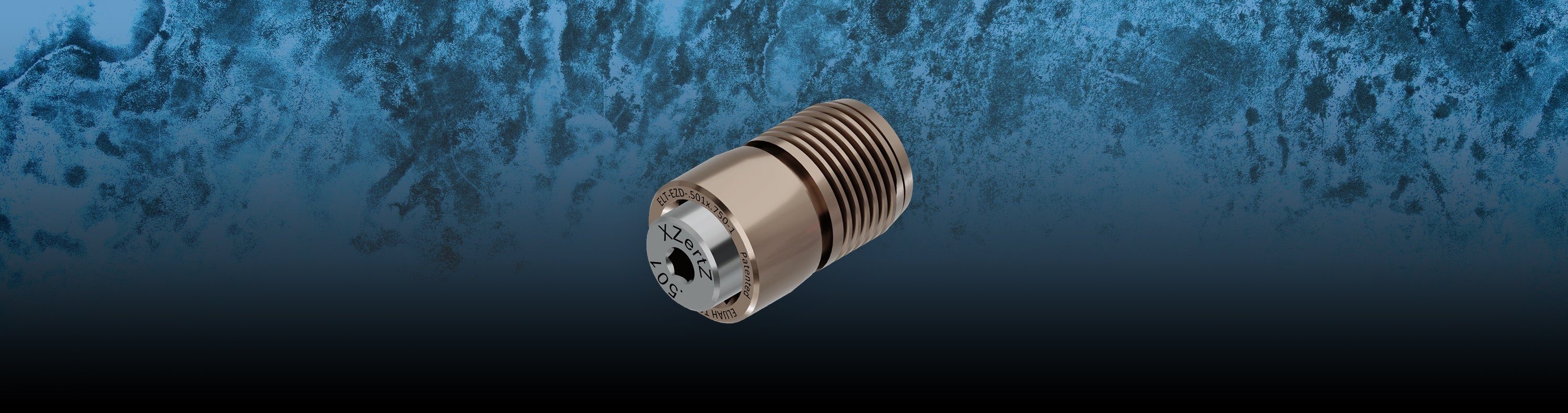

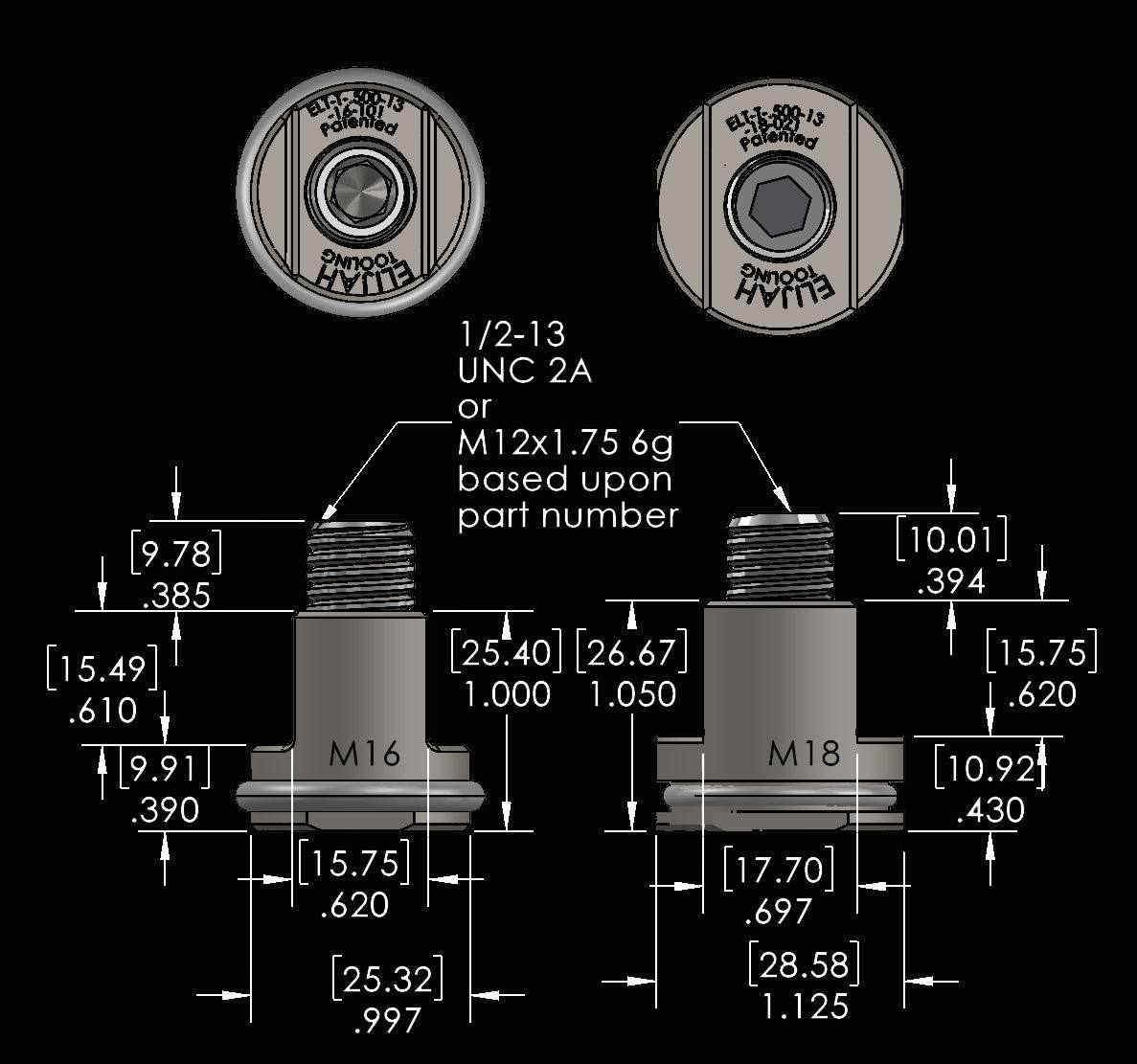

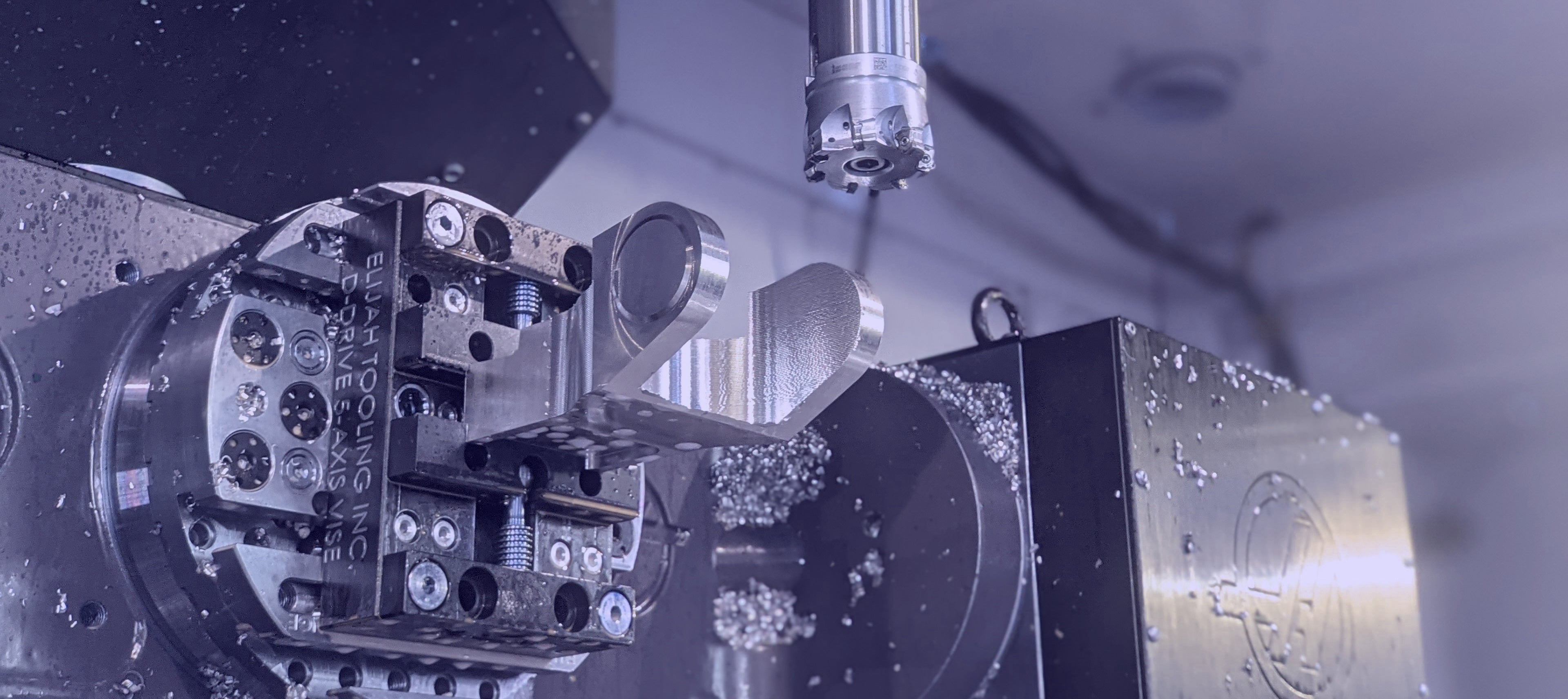

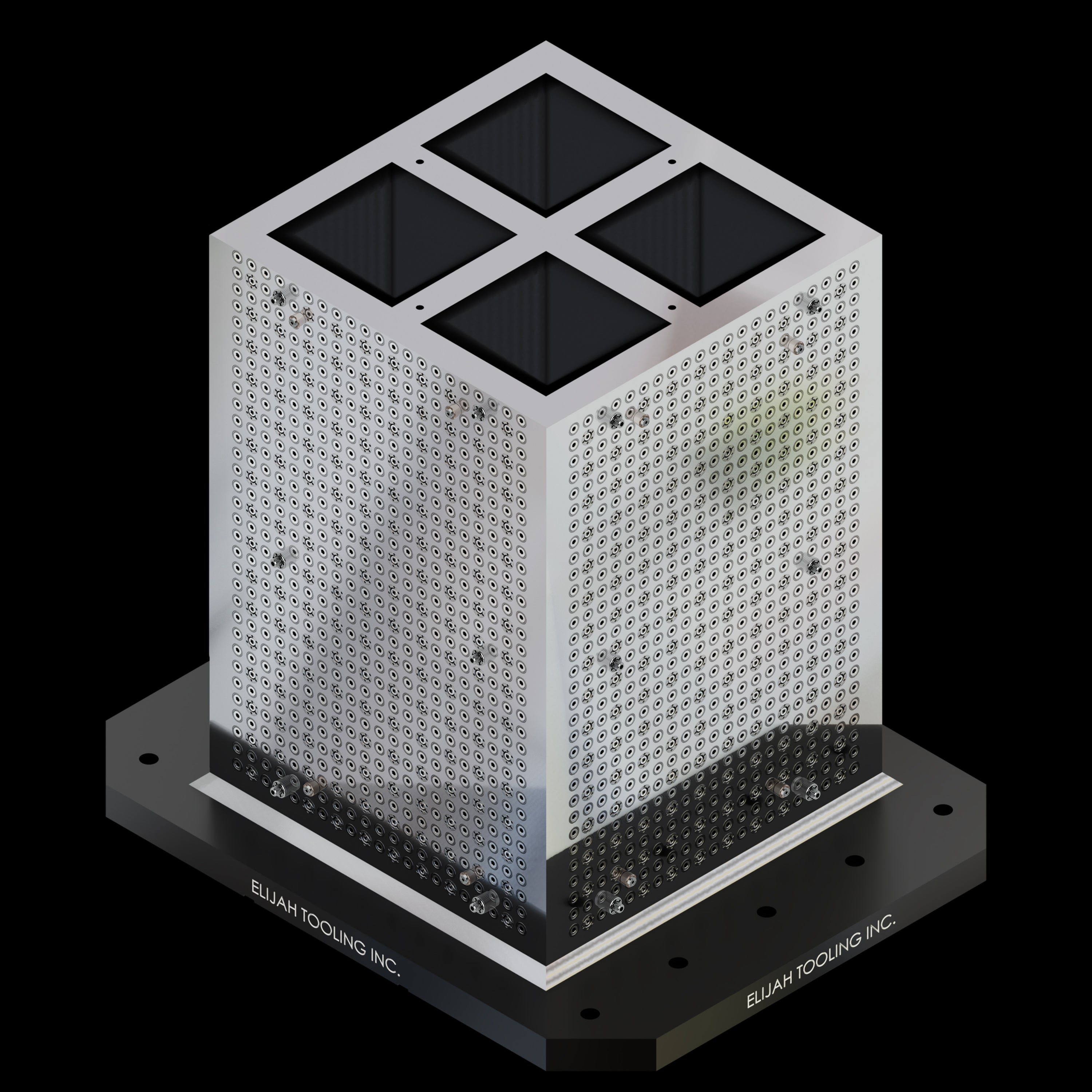

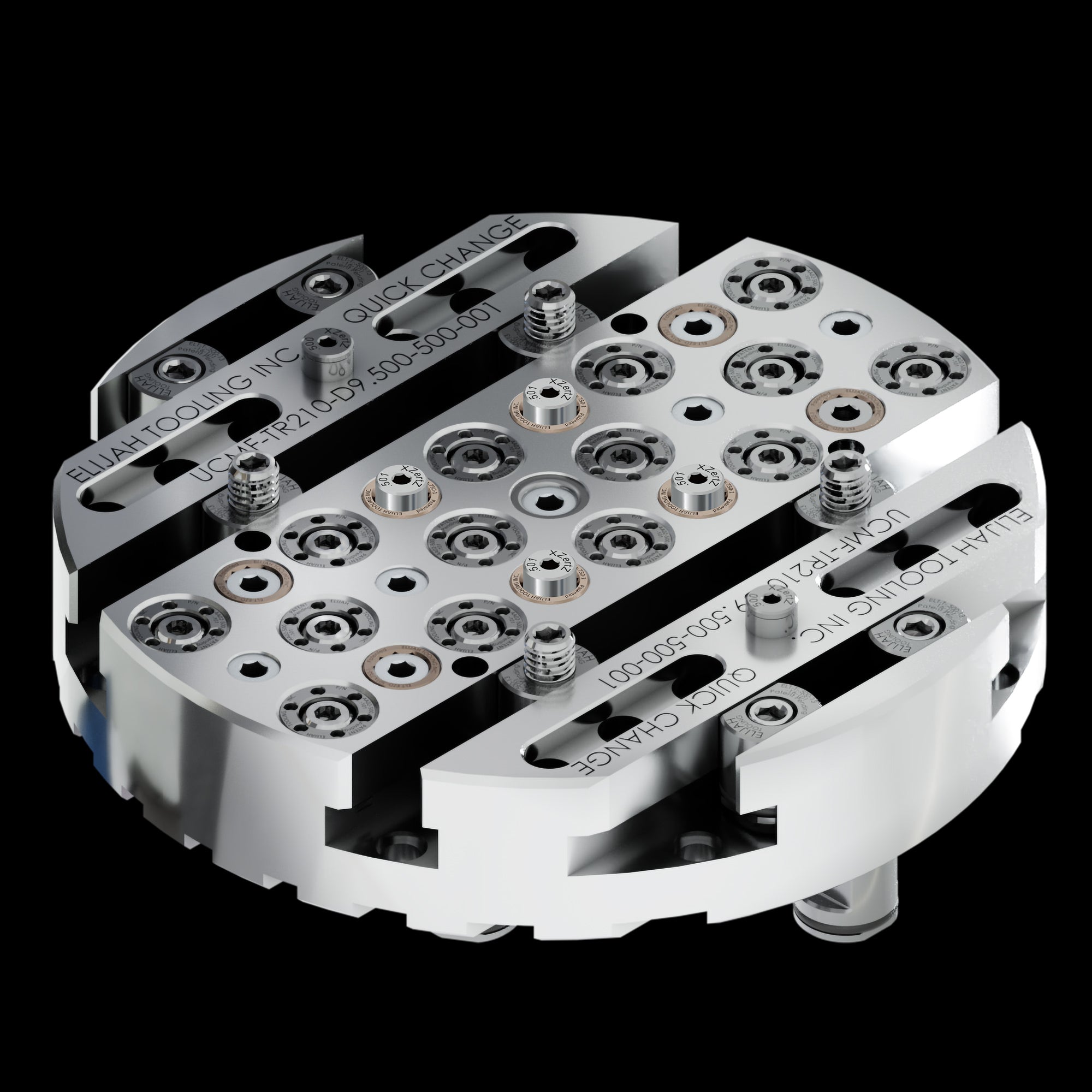

Invert-a-Bolt™ Fastener Clamping

Invert-a-Bolt™ fasteners are unobtrusive, allowing for easy access to the machined part without any interference with the machining process.

Their minimalistic design is unobtrusive yet highly effective, as they firmly grip the part from underneath. This leaves the top view unobstructed and doesn't limit access to the surface being worked on. The CNC machining process can proceed with precision and ease, thanks to the streamlined nature of these fasteners.

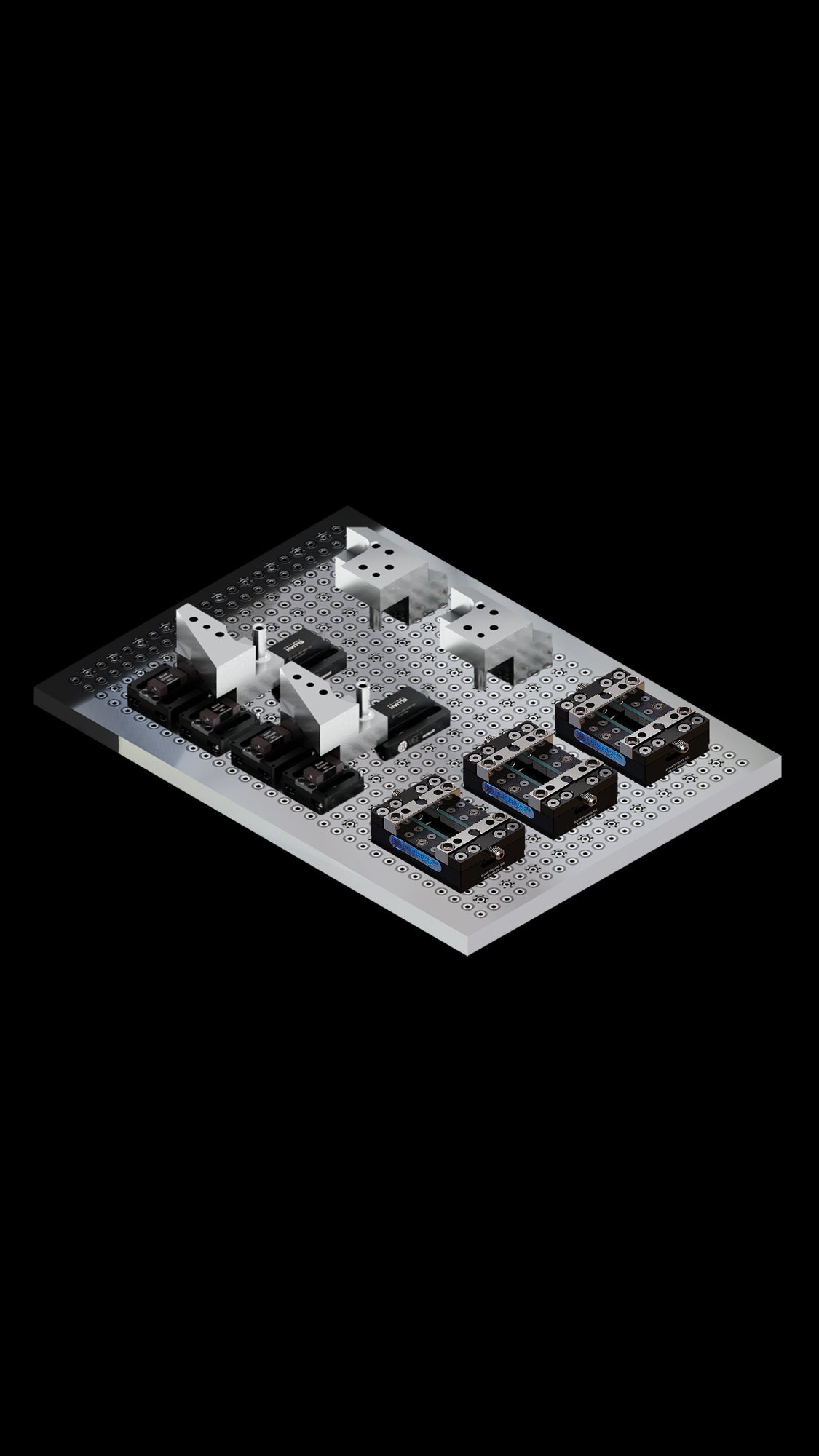

Parts

Workholding

2X

Customers report doubling machining efficiency with Elijah Tooling products.

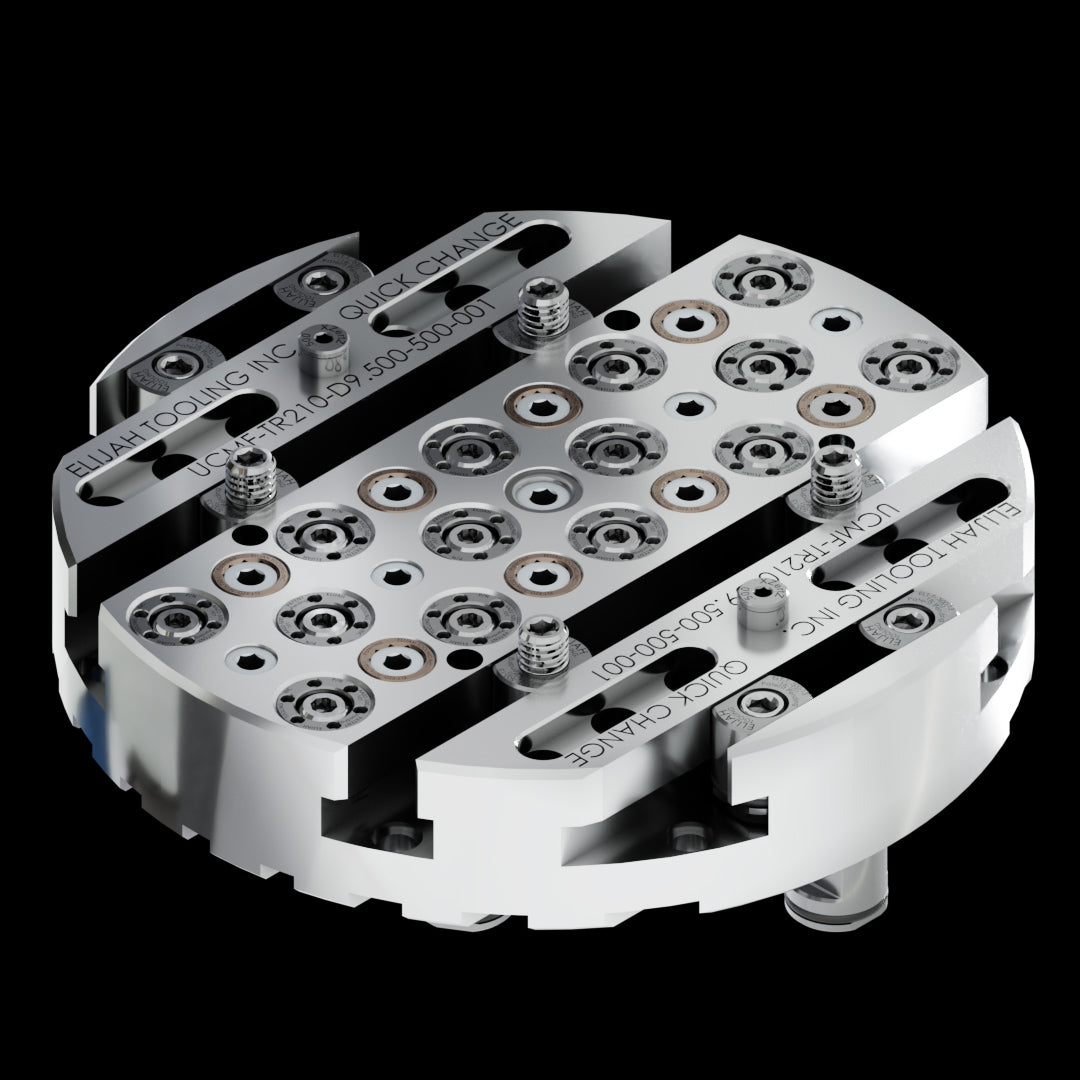

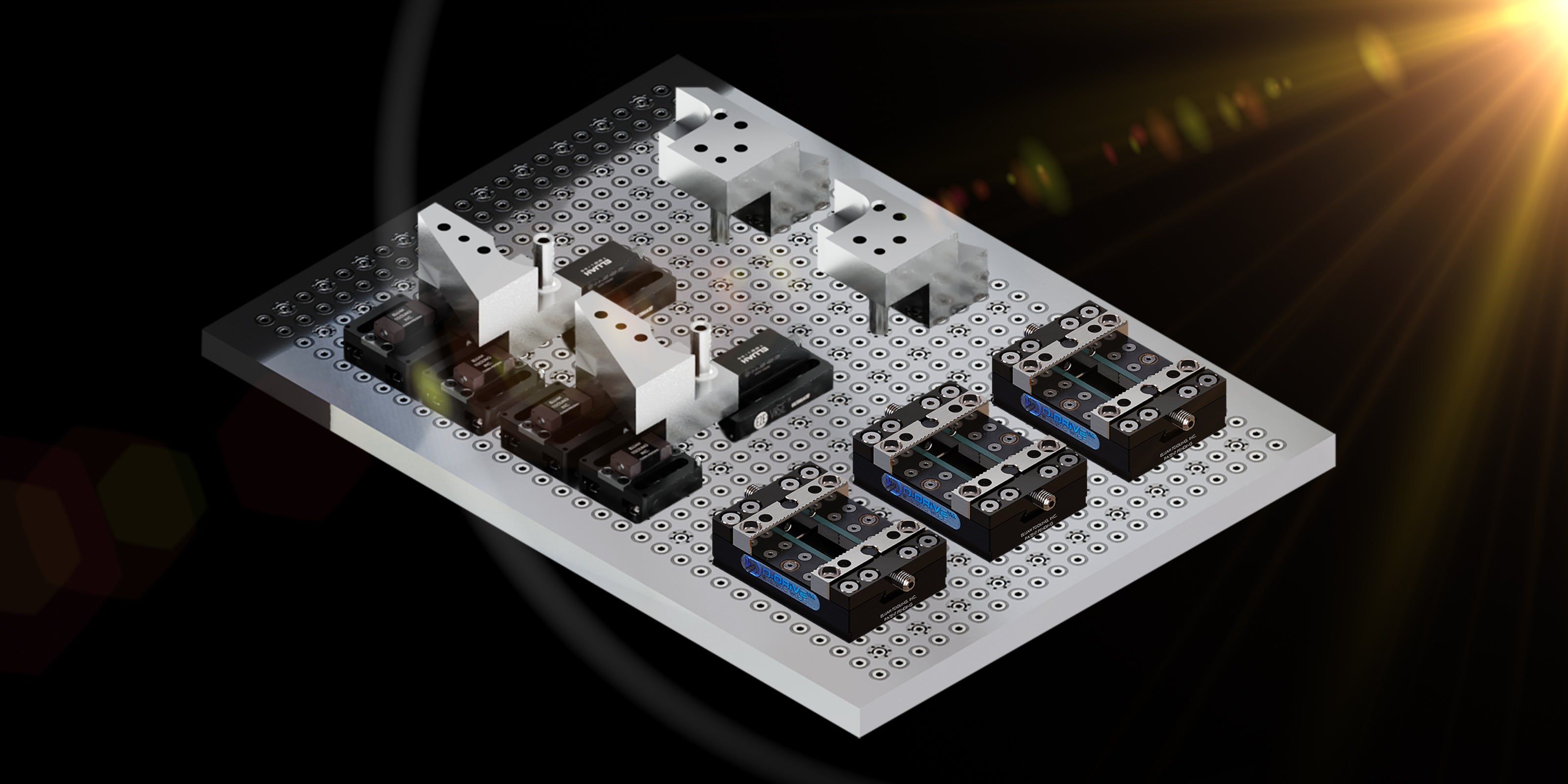

MODULAR FIXTURING MEANS

Endless Possibilities

"Does it really work?"

Testimonials

Steve D. / Cessna Aircraft

"... I built a tool with the invert a bolt system last spring. To date the system has performed admirably. We have had no maintenance on it and no problems!! I am happy with it's performance ..."

Ron W. / Orizon Aerospace

"...the Invert-a-Bolt fixture is working great in our Makino A88 machine...we use Invert-a-Bolt fasteners in our work holding scheme as often as possible..."

Bruce O / Hope Manufacturing

The first Invert-a-Bolts have been used and the personnel on the floor love them... Our efficiency went from 47 to 89 percent the moment we installed Invert-a-Bolts.

All the tools

"I couldn’t be happier with your equipment. Very fast & super accurate repeatability."

"...we cut setup times from hours to minutes..."

"... We have used the invert-a-bolt for quite a while now and it is a very good product.... "

FAQ

Use this text to share information about your product or shipping policies.

Do you ship overseas?

Yes, we ship all over the world. Shipping costs will apply, and will be added at checkout. We run discounts and promotions all year, so stay tuned for exclusive deals!

How long will it take to get my orders?

In most cases where items are in stock, orders received by 3PM CST will ship out the same day. Other orders ship the next business day.

Orders processed here will take 2-4 business days to arrive. Overseas deliveries can take anywhere from 7-16 days. Delivery details will be provided in your confirmation email.

Can I use my own shipper?

Yes. If you would like to use FEDEX or UPS or some other shipper, simply give us your account number to add to the shipment and we'll handle the rest.

What is your return policy?

Items in good condition returned within 30 days of purchasing will receive a 100% refund.

Items returned within 30-60 days will receive a 75% refund.

We do not accept refunds after 60 days.

More return policy information can be found under the "Company" tab at the top of this page.

Any question?

You can contact us through our contact page! We will be happy to assist you.